Aircraft maintenance is an incredibly critical aspect of the aviation industry. Ensuring an aircraft’s safety, efficiency, and reliability requires meticulous attention to detail and regular upgrades and replacements of aerospace parts. Choosing the right aircraft parts suppliers is therefore very important.

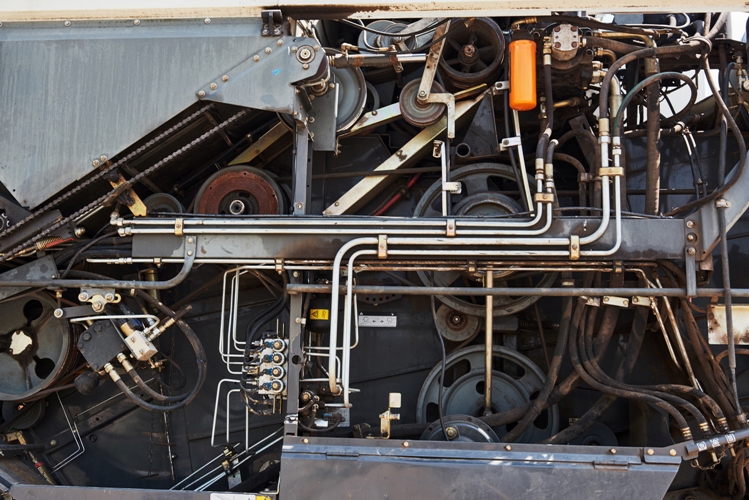

Fundamentally speaking, aircraft maintenance is maintaining, repairing, and upgrading aircraft. Depending on the aircraft type, this can involve everything from checking for leaks and ensuring the engines are working correctly to replacing parts that are no longer made. In addition to safety and efficiency, regular maintenance minimizes AOG and downtime for an aircraft and helps keep costs low.

The importance of upgrading and replacing aerospace parts cannot be overstated.

Upgrades can introduce new features to the aircraft or improve the functionality of existing systems and the integrity and reliability of components through structural fatigue mitigation or replacing electrical wiring and other degraded components.

Aircraft maintenance is a highly regulated, safety-critical, and complex industry. There is an ongoing need in the aerospace industry to develop innovative solutions to address process efficiency without compromising safety and quality.

Ultimately, regular aircraft maintenance is crucial for ensuring the safety of passengers and crew members. It is also essential for minimizing downtime and keeping costs low. The upgrading and replacement of aerospace components is a crucial factor in this.

Here is a brief overview of the significance and benefits of upgrading and replacing aerospace parts as a function of regular aircraft maintenance.

The safety of passengers and crew members is paramount in aviation. Upgrading and replacing aerospace parts are pivotal in maintaining the highest safety standards. Over time, aerospace components experience wear and tear due to various factors such as vibrations, extreme temperatures, and high pressure. These factors can compromise the structural integrity and performance of the aircraft. By upgrading and replacing worn-out or outdated parts, aviation professionals can eliminate potential risks and enhance the safety of flights.

The aviation industry operates within a stringent regulatory framework that mandates regular inspections, maintenance, and adherence to safety guidelines. Aviation authorities require aircraft operators to comply with maintenance schedules and replace critical aerospace parts within specified timeframes or usage limits. Failure to comply can only result in penalties and grounding of the aircraft.

Upgrading and replacing aerospace parts by regulatory standards ensures compliance and reinforces the industry’s commitment to maintaining the highest level of safety.

Upgrading and replacing aerospace parts also contribute to optimizing aircraft performance. Technological advancements continuously introduce new and improved components that enhance efficiency, reliability, and durability. Upgrading these advanced parts can improve fuel efficiency, reduce maintenance costs, and increase operational effectiveness.

By embracing these advancements, airlines can improve their competitiveness, achieve higher profitability, and provide a better travel experience to their customers.

While upgrading and replacing aerospace parts from an aircraft parts supplier requires an initial investment, they can result in long-term cost savings. Worn-out components are more prone to failures and can lead to costly, unscheduled maintenance and aircraft downtime. On the other hand, upgrading to more robust and efficient parts can reduce the frequency of repairs and enhance the overall lifespan of the aircraft.

Furthermore, advanced components often offer better reliability and require less frequent inspections, reducing the labor and material costs associated with maintenance.

The aerospace industry is continuously evolving, with materials, manufacturing techniques, and technology advancements. Upgrading and replacing aerospace parts allow aircraft operators to capitalize on these advancements and stay at the forefront of innovation.

For example, introducing composite materials in aircraft structures has revolutionized the aerospace industry, offering weight savings, improved fuel efficiency, and increased strength. By embracing such innovations, airlines can maintain a competitive edge and meet passengers’ evolving needs and expectations.

Aircraft maintenance is a complex and essential process that ensures aircraft safety, reliability, and performance. Upgrading and replacing aerospace parts are crucial aspects of this maintenance process.

By prioritizing safety enhancements, compliance with regulatory standards, performance optimization, cost-effective maintenance, and embracing technological advancements, aircraft operators can ensure the highest levels of safety, operational efficiency, and passenger satisfaction.

1618 N Ohio Street

Augusta, KS. 67010

2024 © Aircraft Parts. All Rights Reserved.

Designed By Digital SFTware